It is well known in the industry that chocolate has a smooth surface, thus, the ink cannot be dried, the pattern cannot be attached, and it is easy to be blurred by rubbing when edible ink is used. Therefore, the traditional chocolate printing mainly adopts pad printing or transfer printing, but these methods are often single in color and monotonous in pattern, resulting in low grade of products.

In order to break through the barrier of chocolate printing technology, we developed a chocolate coating agent, which can be sprayed on the surface of food, making food printable, so as to give food personality, colorful patterns. It is widely applied to products with smooth surface or products unable to adsorb edible ink, such as chocolate, hard candy, etc. It solves the problem that food cannot be printed and provides a powerful innovation tool for food production and sales enterprises.

In the confectionary industry, there is a wide variety of patterns, which are most commonly seen in cake and chocolate shops. These patterns are usually printed on edible chocolate transfer paper as they are not suitable for traditional food printing methods. The main reason for this is the smooth texture of chocolate, candy and similar foods, which makes them impervious to edible ink adhesion. This leads to a time-consuming drying process and a tendency to smudge, thus raising the issue of how to effectively address this issue.

Chocoprint coating agent:

Chocolate printing solutions for different output amount requirement:

1. Solution to Chocolate Printing in small QuantityA3+ Flatbed Food printer, Edible ink and chocolate coating agent are commended for printing edible Image Chocolate. The printing process includes the following four steps.

Step 1: Pour Chocolates into moulds

Step 2: Manually spray the Chocoprint Coating Agent

Step 3: Chocolate Printed via A3+ Flatbed Food Printer

Step 4: Butterfly chocolates completed

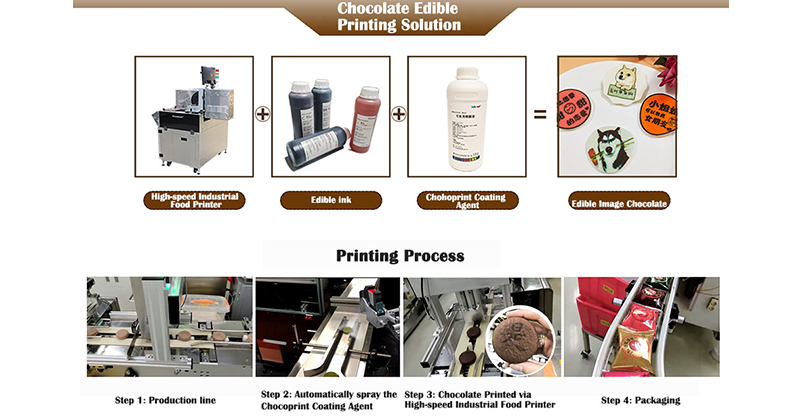

2.Solution to Chocolate Printing in large Quantity

542 high-speed industrial food printer, Edible ink and chocolate coating agent are commended for printing edible Image Chocolate. The printing process includes the following four steps.

Step 1: Put chocolates on the production line

Step 2: Automatically spray the Chocoprint Coating Agent

Step 3: Chocolate Printed via High-speed Industrial Food Printer

Step 4: Image chocolates completed for packaging

Keywords:

If you have questions or need further details, please contact us by email info@foodprinttech.com or chat online.

About Foodprinttech

Commonly

referred to as Foodprinttech, Wuhan Food Printing Technology Co., Ltd.

is a renowned manufacturer specialized in producing cutting-edge food

printing machinery. Belonging to the same group which includes Sino

Joinsun, Hescare and Kyhink, it's dedicated to R&D, production and

sales of High-speed Food Printers, Flatbed Food Printers and consumables

like accompanying edible ink.

With hundreds of R&D personnel, senior equipment engineers, and base production personnel in the two R&D centers in Beijing and Wuhan. Foodprinttech has always been one step ahead in the digital food printing field.

With the cultivation of core competitiveness in mind, Foodprinttech carries out school-enterprise cooperation actively, and builds a research and development platform jointly (in cooperation with famous domestic universities ), with a licensing unit for academician workstation and doctoral workstation in Hubei Province.

Consumers'

health always comes first. Our circulation of food adheres to strict

national and international certifications, and it also undergoes

rigorous testing by Third-party SGS and ISO22000. Our equipment holds CE

and CQC certifications, along with a design patent. Additionally, the

printer's edible ink is certified by FDA, Kosher, and Halal, providing

complete assurance of safety.

Comments

Post a Comment